煤矿行业案例

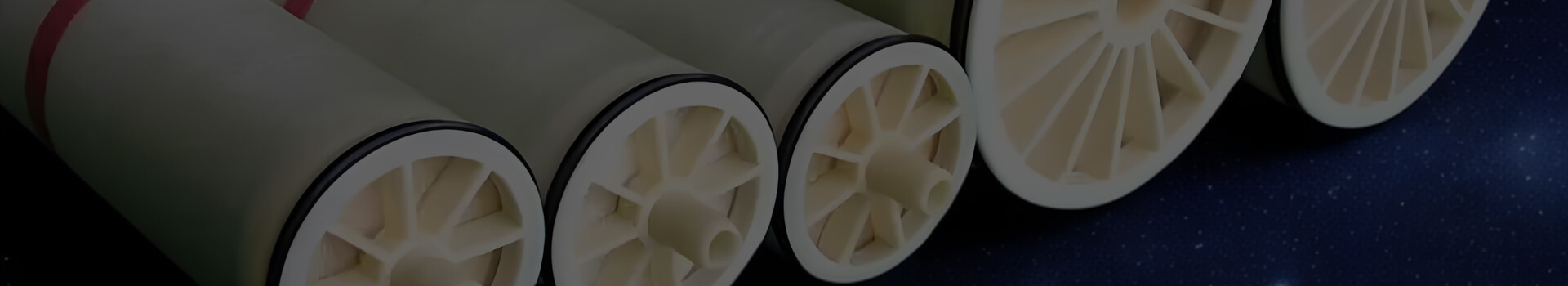

在高盐高难度废水处理领域,过去长期依赖进口膜产品,不仅采购价格高昂,还常面临售后响应慢、技术支持不及时的难题,给项目推进和长期运维带来诸多不便。而海纳膜在鄂尔多斯石**煤矿废水处理零排放项目中的成功应用,恰好打破了这一局面。作为国产膜替代进口膜的典型代表,海纳膜针对煤矿废水高盐、高污染的复杂特性专项研发,通过优化膜材料结构与抗污染设计,有效解决了传统进口膜易堵塞、清洗频繁的痛点,在长期运行中始终保持稳定的处理效能与优质产水,为项目顺利达成零排放目标提供了核心支撑。实现 “高性能 + 高性价比” 的双重优势,成为中国膜产业打破进口垄断、实现自主可控的有力见证。

0571-88587247

0571-88587247